What is the difference between welding and metal fabrication

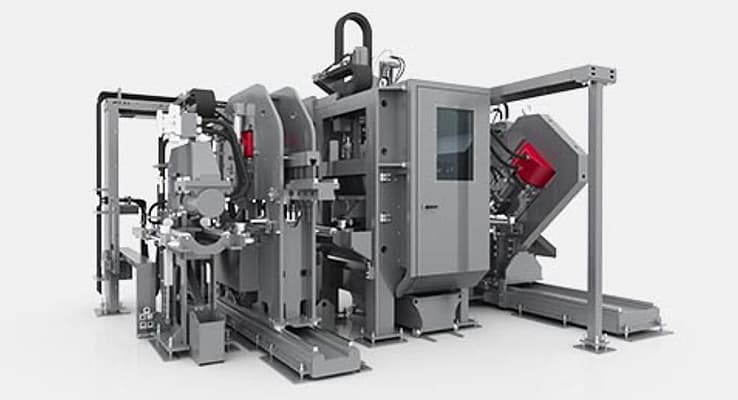

Gulf States Saw & Machine Co. understands that not every fabricator has the same needs. This is due to the fact that processes and the natures of tasks can be different. We've gathered the most reliable structural fabrication machinery available to suit your needs. We have the best structural machines available for all price ranges.